[HINDI] PULVERIZED COAL FIRED BOILER ~ WHAT IS PF .

Nov 06, 2017· [HINDI] PULVERIZED COAL FIRED BOILER ~ WHAT IS PF BOILER ~ DOMINATOR OF THERMAL POWER PLANTS Unacademy Studios Bridge. ... Why pf boilers is used in majority of thermal power plants

WhatsApp)

WhatsApp)

Nov 06, 2017· [HINDI] PULVERIZED COAL FIRED BOILER ~ WHAT IS PF BOILER ~ DOMINATOR OF THERMAL POWER PLANTS Unacademy Studios Bridge. ... Why pf boilers is used in majority of thermal power plants

Owners of existing coalfired power plants today have a very compelling case to consider: the addition of, or conversion to, natural gas firing. Lower natural gas prices and more stringent air emissions regulations, in combination with the ability to burn natural gas with its inherently lower emissions

what is coal thermal firing plant Mine Equipments. The 1,216 MW Sual CoalFired Thermal Power Plant _02 The Sual CoalFired Thermal Power Plant in Sual, Pangasinan, Philippines, has an installed capacity of 1,216 MW. It is composed of two (2) generating units . Marketing Budget.

power plant, less coal needs to be fired. This reduces the burden on the coal handling system, conveyers and crushers. Also, since dryer coal is easier to convey, this reduces maintenance costs and increases availability of the coal handling system. Crushed coal is fed into the bunkers from where it flows by gravity to the coal feeders.

Given that cofiring requires large amounts of biomass fuels, cofiring typically works best with large coalfueled utilities that have materials handling capability already on site. However, other industrial users – cement plants, heating plants, etc. – could also make use of biomass cofiring.

Coal fired power plants are a type of power plant that make use of the combustion of coal in order to generate use provides around 40% of the world''s electricity and they are primarily used in developing countries. Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal ...

May 04, 2011· Table shows the estimated cost of coalfired power plants in the United States in 2016 dollar prices based on data from the US government''s Energy Information Administration (The US EIA). This analysis suggests that the capital cost of an advanced PC power plant is 3636/kW. When carbon capture and storage is added to this, based on postcombustion capture, the cost rises to .

May 31, 2017· Coalfired power plants, or coal burning power plants, produce electricity by burning coal in a boiler to produce steam. The steam produced, under high pressure, flows into a turbine, which spins a generator to create electricity. Coal is the largest energy source used to generate electricity at power plants.

The energy efficiency of a conventional thermal power station is defined as saleable energy produced as a percent of the heating value of the fuel consumed. A simple cycle gas turbine achieves energy conversion efficiencies from 20 to 35%. Typical coalbased power plants operating at steam pressures of 170 bar and 570 °C run at efficiency of 35 to 38 %, with stateoftheart fossil fuel ...

Nov 02, 2017· This video describes the complete demonstration that how coal fired boiler actually works by an animated video.

New coalfired generating plants are not showing up in the Elderly plants are retiring in large numbers. But other parts of the world continue to develop coal generation. Advances in ...

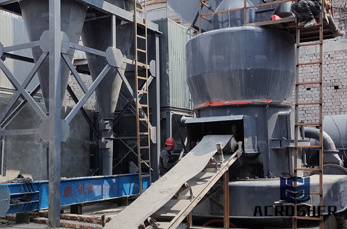

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels.

High Ash Coals – A challenge to Power Plants – Optimisation of combustion in high ash coal fired boilers is of special interest due to the organic and inorganic mix up and the large amount of variation in the organics. One such experience with Indian low reactive coal in a tangential fired steam generator of 670 T/hr capacity is given here.

of coal fired thermal power plants of capacity range 30–500 MW. The focus is on primary energy effects—combustion, heat transfer, and flow hydrodynamics. ... Firing coals with very low VM ...

Coal Combustion Nadine Spitz Environmental Engineering BenGurion University Contents What is coal? Formation, sources, applications. Coal combustion description. Coal power plants and air pollution: Mechanisms and control technologies. Coal and air pollution in Israel. Coal – what is it? Coal Coal Sources Coal is the world''s most plentiful ...

A boiler or Steam Generator (prime mover) is an integral device in a fossil fuel power plant used to produce steam by applying heat energy to water. A boiler incorporates a furnace in order to burn the fossil fuel (coal, gas, waste etc.) and generate heat which is transferred to water to make steam.

The largest pressurised fluidised bed power plant in operation is a 360 MW unit in Japan. This plant, with a supercritical boiler, has a claimed efficiency of 42%. Although commercial fluidised bed power plants with capacities of over 400 MW are available, the units have not proved as efficient as supercritical PC power plants for coal combustion.

Jun 22, 2017· How much do ultrasupercritical coal plants really reduce air pollution? ... coalfired plant using subcritical technology will need to burn coal at a thermal input rate of 1000 MW / .

Dec 21, 2019· For indirect cofiring, the ash of the biomass resource and the main fuel are kept separate from one another as the thermal conversion is partially carried out in separate processing plants. As indirect cofiring requires a separate biomass energy conversion plant, it has a relatively high investment cost compared with direct cofiring.

Jan 13, 2015· Coalfired power plants. ... electricity is generated in conventional thermal power plants using steam. Coal or natural gas is burned inside boilers at a very high temperature. ... coal is firing ...

Thermalbased power plants can produce electricity from coal or other fuel sources. The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption. Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2.

Coalfired power plants using pulverized coal or lignite as fuel generate large quantities of flyash as a byproduct. With the increase in commissioning of several super thermal power plants with large capacity and with the increasing use of low grade coal of high ash content, the amount of generation of ash from them is becoming very large.

Jan 15, 2019· Pulverized coalfired Boiler or Pulverized fuel Boiler. A pulverized coalfired boiler is an industrial boiler that generates thermal energy by burning pulverized coal. How does a steam boiler work? In pulverized coal fired boiler,The coal is pulverized to a fine powder, so that less than 2 % is +300 micro meter and 70 – 75 % is below 75 ...

Also upgrading some existing coal plant system to super or ultra_super critical operation results in improvement in efficiency and hence justify the extension of the life of the plant. And of course; improving the efficiency of the coal_fired power plant will make us use less coal per unit of energy. Coalfired power plant environmental impact:

WhatsApp)

WhatsApp)