Concrete LCA Webtool

Ground Meal Dry raw grinding, ball mill Dry raw grinding, tube mill Dry raw grinding, vertical roller mill Wet raw grinding, tube mill Wet raw grinding, wash mill Raw Meal Blending/ Homogenization

WhatsApp)

WhatsApp)

Ground Meal Dry raw grinding, ball mill Dry raw grinding, tube mill Dry raw grinding, vertical roller mill Wet raw grinding, tube mill Wet raw grinding, wash mill Raw Meal Blending/ Homogenization

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined

Introduction of GGBS vertical roller mill. GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS) into small (fineness:cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for readymixed concrete production, for which the percentage ...

Dec 18, 2012· Cement raw materials grinding mill, raw mill, cement mill. The use of the vertical mill normally reduces total . 4 and 6roller mills to suit the . The parameters used in the control of the raw meal are lime . »More detailed

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

how to control residue in vertical roller mill for raw . 18/12/2012· Cement raw materials grinding mill, raw mill, cement mill. The use of the vertical mill normally reduces total 4 and 6roller mills to suit the The parameters used in the control of the raw meal are lime

Raw meal grinding in Northern Iraq. In January 2011, Sinoma (Suzhou) Construction Co. Ltd. acting as General Contractor placed a repeat order for an MPS 5000 B vertical roller mill for raw material grinding. The grinding plant designed for a capacity of 450 t/h will be set up in Mass Global Company''s third 5000 t/d cement production line in ...

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, ... for raw meal, clinker and coal grinding due to their lower capital cost ... Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control. This automation solution stabilises the VRM to allow

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

Cement grinding Vertical roller mills versus ball mills RuCEM . applications of the vertical roller mill for cement grinding are less prevalent. The twocompartment ... cement is ground much finer than raw meal. • the feed to a ... specific surface area (Blaine) or a sieve residue of the product.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, .

fls vertical roller coal mill lemedievalbe. Egypt: Loesche is supplying three vertical roller mills for the Egyptian raw meal, a cement mill with an output of 350t/hr as well as a coal mill with an output of 45t/hr India: FL has signed a contract to deliver an OK 4 cement mill

Raw Mill Cement Additives vertical in line raw mill for iron ore plants Power Plant,Coal Mill Thermal Power Plant For Overseas from Mine Mill Supplier or coal mill thermal power plant is also called raw meal vertical roller mill, and it is the core can cater to 1000 10000t/d cement production line raw material supply.

for adaptation to changes in raw meal requirement. In addition, the mill has extremely maintenancefriendly design features. For instance, the two opposite grinding rollers can be swung hydraulically out of the mill housing; the two roller units remaining in the mill then continue the grinding process. The new mill system from Krupp Polysius ...

Vertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is .

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small roller mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while h

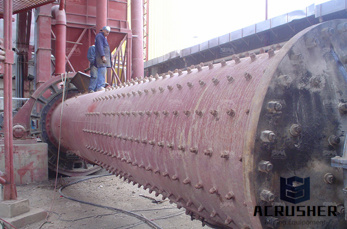

VERTICAL ROLLER MILLS KTM Compact design Comfortable operation and maintenance KTM series of wide capacity range. Application of KTM mills KTM vertical roller mills are used for grinding of cement, lime, glass, as well as a number ... Assembly of a mill for 150 t/h of raw meal With 4 runners in PSP''s work shop:

Fm3640 Raw Material Vertical Roller Mill /raw Meal Vrm Mill, Find Complete Details about Fm3640 Raw Material Vertical Roller Mill /raw Meal Vrm Mill,Vertical Roller Mill,Raw Material Vertical Roller Mill,Raw Meal Vrm Mill from Mine Mill Supplier or ManufacturerJiangsu Pengfei Group Co., Ltd.

Raw meal grinding in Northern Iraq. In January 2011, Sinoma (Suzhou) Construction Co. Ltd. acting as General Contractor placed a repeat order for an MPS 5000 B vertical roller mill for raw material grinding. The grinding plant designed for a capacity of 450 t/h will be set up in Mass Global Company''s third 5000 t/d cement production line in ...

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

The mill is airswept, and the fines are carried away in the gas stream. Crushing and drying are efficient, but the product is coarse (around 100 µm), and is usually reground in a separate ball mill. Roller mills. These are the standard form in modern installations, occasionally called vertical spindle mills. In a typical arrangement, the ...

ZKRM Vertical Roller Mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mine. Types: 1.

Application of Vertical Roller Mill. Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Vertical Roller Mill. Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum .

WhatsApp)

WhatsApp)