YouTube

Nov 19, 2012· The machine is designed to do the following types of grinding: double lead grinding, tapper thread grinding, single flank grinding, dual pressure angle grinding, plug thread gage, rolling die ...

WhatsApp)

WhatsApp)

Nov 19, 2012· The machine is designed to do the following types of grinding: double lead grinding, tapper thread grinding, single flank grinding, dual pressure angle grinding, plug thread gage, rolling die ...

A grinding wheel is an expendable wheel that carries an abrasive compound on its periphery. These wheels are used in grinding machines. The wheel is generally made from a matrix of coarse particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections are

China Gear Grinding Machine manufacturers Select 2020 high quality Gear Grinding Machine products in best price from certified Chinese Grinding Equipment manufacturers, Grinding Mill suppliers, wholesalers and factory on

Machine Tool Structures, Volume 1 deals with fundamental theories and calculation methods for machine tool structures. Experimental investigations into stiffness are discussed, along with the application of the results to the design of machine tool structures.

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.

Nov 27, 2018· Surface Grinding Machine: Grinding Process, Specifications of Grinding wheelDetailed PDF: Grinding is the conventional finish machining Process used for producing a good surface finish on the components. The abrasive particles present on the surface of a grinding wheel will be acting as a single point cutting tools for removing the material from the workpiece.

Use And Performance Of The Vehicle Repair Industry Is Grinding To Repair The Vehicle Flywheel Special Machine Tools, Has A Simple Structure And Reliable Performance Characteristics Such As Grinding...

Dec 23, 2018· Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more. The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machining. ... The selection of the structure of the grinding wheel ...

Centerless Grinder > CNC Series. Rigid Machine Structure; (1) The machine structure is manufactured from high quality ... (2) With thrufeed grinding, the upper slide provides a surface contact... Get price; Stone grinding machine for skis, snowboards and cross country skis. Omega S 350 The stone grinding machine for skis, snowboards and cross ...

Milling Machines A milling machine is a power driven machine that cuts by means of a multitooth rotating cutter. The mill is constructed in such a manner that the fixed workpiece is fed into the rotating cutter. Varieties of cutters and holding devices allow a wide rage of cutting possibilities.

This work presents a research on the static structure and modal analysis of precision grinding machine bed. The solid model is created with 3D design software SOLIDWORKS and analyzed by FEA ...

Construction of the grinding wheel. In order to suit the grinding wheel for different work situations, the features such as abrasive, grain size, grade, structure and bonding materials can be varied. A grinding wheel consists of the abrasive that does the cutting, and .

Don''t worry! if you not learned yet you can check my complete guide on grinding machine where I mentioned the parts, types, and operations of a grinding machine. So hello viewers in today''s article you learn about the definition, types, grain, grade, structure, bond, specifications, and selection of a Grinding .

Nordic Ultratune uses the Mantec Ski Numericontrol 140 CNC stone grinding machine. The Mantec grinder is the most advanced machine in North America today. It produces very precise and well defined structures with the best reproducibility. Pick one of our listed grinds below for most conditions.

Oct 28, 2004· Models with turretmounted grinding spindles are the most flexible and the best suited for optimum results in singlesetup processing. These models can automatically switch the grinding angle to do ID, OD and face grinding on the same machine. Typically, the turret is .

A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines.. The wheels are generally made from a composite material consisting of coarseparticle aggregate pressed and bonded together by a cementing matrix (called the bond in grinding wheel terminology) to form a ...

Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines. Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry.

【DURABLE STRUCTURE】 Sharpening grinder machine owns a reasonable structure and durable material, easy to install and operate. Cast iron and 45# steel material significantly improve stability and longevity. 【HIGH ACCURACY CONVENIENCE】 Two kinds of replaceable wheels promote grinding accuracy and working efficiency.

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987).The two most common grinding applications are cylindrical grinding and surface grinding.

The first grinding machines were used in the 12 th century as grinding mills, which were converted from conventional grinders. Cylindrical Grinding machine for metalworking. Areas of Application of Metal Grinding Machines. There are a number of different types of grinding machines for sale for sheet metal work, and they are applied for various ...

Burri Grinding And Profiling Machines MTB Machine. Why Burri and Machine Tool Builders is a Great Solution Burri machines are designed and developed pletely at Burri facilities in Germany Our Software Engineering develops a dialogue controlled user interface for all gear grinding and profiling machines which proves itself with simple menu navigation and logic structure

The structure is indicated by a number varying from 1 (very closed structure) to 15 (very open structure. On every grinding machine wheel, the manufactures are limit to give the following information. in specified sequence about the, Abrasive used (A or C) Grit number (ex: 46)

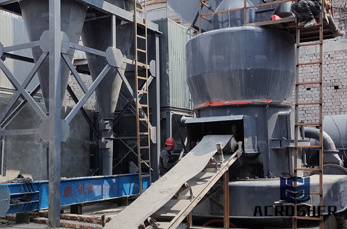

Structure of Commercial Chili Powder Grinding Milling Pulverizing Machine: ... While crushing materials, a large amount of air is absorbed by the turbine, which acts as a cooling machine, grinding materials and conveying fine materials. The fineness of processed powder depends on the nature of the material and the size of the screen, as well as ...

Our electric feed material grinding machine is composed of feeding hopper, rotor, sieves, draught fan, Inquire Now; Spice Processing Machine Spice Grinding Machine This machine is manufactured by using optimum quality cast iron and mild steel. This machine is mainly used for grinding .

WhatsApp)

WhatsApp)