Ball Milling University of Massachusetts Boston

Design Safer Chemicals ... Ball milling should be considered as a potentially attractive solution for solventfree synthesis. 21 Solvent free Onepot process Tip of iceberg . Reference

WhatsApp)

WhatsApp)

Design Safer Chemicals ... Ball milling should be considered as a potentially attractive solution for solventfree synthesis. 21 Solvent free Onepot process Tip of iceberg . Reference

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Jan 12, 2018· Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance. It uses Polyurethane Skate wheels and 608ZZ bearings. It has a laptop power supply and a basic ...

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as .

Mar 31, 2008· Best Answer: A ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium steel.

Sign up for our email list to stay connected and up to date with our latest projects!

Mar 29, 2019· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

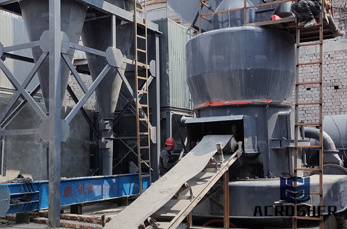

Nov 06, 2016· t/d ball grinding mill for Cement, slag, coal, iron ore beneficiaiton. Tel:+ Email:sales Web:

Feb 18, 2019· Dec 04, 2012ball mill foundation design. Home ball mill foundation design. sbm company is a research and development, production, For the foundation design and . ball mills foundations design ...

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

ball mill design software free download grinding mill equipment Ball mill ore crusher price A ball mill is a type of grinder used to grind materials into extremely fine powder for Get More Info ball mill design software free download learning ... ball mill design calculation free download

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected.

A Parametric Design of Ball End Mill and Simulatin. and the calculation for a ball end mill, a ball end mill parametric design system is built by development technology with CATIA 3D modeling software and Visual Basic With this system obtaining the model of the ball end mill, the simulation is processed in Third Wave AdvantEdge software The main contents of this paper are: 1

China Leading Ball Mill Design Calculation/Ball Mill Ball Mill is mainly used to grind materials in mineral, cement, refractory, chemical industry, etc. Ball Mill has dry and wet ways. When wet Ball Mill works, certain water and other liquid will be added into materials to increase flowability of materials, so the capacity is increased.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

How to Size a Ball Mill Design Calculator Formula ... Ball milling – a ball mill with a diameter of meters, inside new liners, grinding wet in open circuit. ... interactive software that could be used as an inexpensive means of providing a semiquantitative check on a grinding mill design. In addition the software is designed to ...

Every mining operation has a unique grinding process. has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your mill.

Visualmill is mecsofts flagship standalone milling software modulet is ideal for mold, die, tooling, wood working, prototyping and general machining. Chat Online; A Parametric Design Of Ball End Mill And Simulating . Chang, liyong 2016 a parametric design of ball end mill and simulating processasters thesis, concordia university. Chat Online

WhatsApp)

WhatsApp)