Gravity Concentration Plant for rock gold YouTube

Nov 21, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Nov 21, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Gravity Concentrating Pilot Plant For Eluvial, Vein Gold Ore This is a small scale gold ore processing plant, that uses gravity concentration to separate the gold from the rock material. It had a capacity of 1/2 ton per hour, and was used in West Africa.

Here is how a gravity gold concentrator (centrifuge) works as a separator: Make sure the concentrator has been correctly assembled and that all bolts have been tightened. If required, attach a funnel to the material feed inlet. If necessary, connect a hose to the tailings outlet. Place the concentrator on a raised structure such as blocks.

The following study shows the improvement and simulation of a gold recovery plant of 24 t/day of capacity by gravity concentration, flotation and leaching.

Probably the first reported underground gravity gold processing plant was operated between 1991 and 1999 by Welsh Gold PLC at their Gwynfynydd gold mine in north Wales, United Kingdom. The plant was permanently installed in old workings and was a traditional gold concentration process. The ore was found to be amenable to a simple

Principles of gravity concentration Gravity concentration methods separate minerals of different specific gravity by their relative move ment in response to gravity and one or more other forces, the latter often being the resistance to motion offered by a viscous fluid, such as water or air.

The Consep Acacia Reactor is a complete intense leaching plant that maximises the recovery of gold from gravity concentrates. Often used downstream from FL Knelson Concentrators, the Acacia produces the optimum solidliquid interaction for maximised gold leaching kinetics by using an up flow fluidised reactor as opposed to complex mechanical agitation.

The heart of the iCON Gold Recovery family is the world renowned iCON i150 Concentrator. iCON uses classification and enhanced gravity in its centrifugal concentrators to ensure that you are recovering the most gold possible.

Jig concentrators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity (relative density).. The particles would usually be of a similar size, often crushed and screened prior to being fed over the jig are many variations in design; however the basic principles are constant: The particles are ...

The object of gravity concentration is the separation of the heavy valuable mineral from the light worthless gangue. Complications are often introduced by the fact that various base minerals must be separated from one another, an ore being subdivided into several products. Most gold ores, however, only require separation into two parts—the "concentrates," in which the precious metal is ...

Gold Bearing Ashes Gravity Concentration. Gravity Concentration is sorted using the relative density between the mineral particles, particle size, shape and the difference in the different media (water, air, or other relatively high density liquid) in the rate and direction of movement, so that separate from each other beneficiation .

of the major plants incorporated gravity concentration followed by cyanidation ofthe bulk ore, up to 73per cent ofthe gold being recovered by gravity concentration when thegoldwasrelatively coarse. Inthis paper weshall attempt to put the argument for gravity concentration inamore balanced light, especially sincecomputer correlation

augmented by historical plant data for the treatment of the MVR and MSeries reef ores between 1989 and 2001. The testwork program included preliminary assessment of various flowsheets, including: 1. SAG milling and/or fine crushing to –2mm and gravity concentration to 15% of feed mass followed by

We will soon be redirecting to our updated Falcon Gravity Concentrators pages on Please visit our new web site for all of your Falcon Gravity Concentrators, milling, sizing, material scrubbing, gravity concentration and modular plant needs. We look forward to hearing from you.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The specific gravity of gold is, so it is times as dense as water. When separating free gold from a typical quartz deposit, gravity concentration must separate based on specific gravities of and, for gold and quartz respectively.

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching. Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold.

IPJ Gangue Rejection and Preconcentration Plant Results Match CGR Lab Work. Full scale installations of the InLine Pressure Jig (IPJ) continuous gravity recovery circuits at Pirquitas (Silver Standard Resources) and Kloof (Gold Fields) provide further evidence of the strong.. | 01 July 2011

Innovative Gold Plant Design for Better Returns . Gekko also offer a readymade modular plant known as the Gravity Flotation Intensive Leach (GFIL) system. GFIL is a complete offtheshelf gold processing modular plant designed to advance traditional whole ore cyanidation. It''s ideal for mines and ores with: Restricted cyanide use permissions

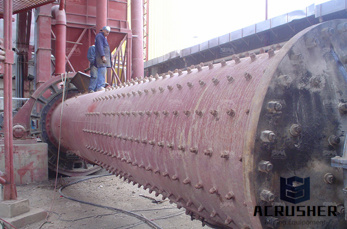

Gold gravity processing plant for small and medium scale mineral processing shaking tables are designed to wet gravitybased then do an excellent job of recovering small gold particles even with a fairly high feed rate plant more than 200 units of the sea,Gold ore gravity concentration plant .

gravity concentrating pilot plant for eluvial. Aug 11, 2016 At the Gold ore Processing Plant, gold and silver are extracted from the Gravity Concentrating Pilot Plant For Eluvial, Vein Gold Ore This is a Chat online Some factors influencing gold recovery by gravity concentration

Gravity Concentration Equipment Washing Screening Equipment Sand Washing Equipment Gold Leaching Cyaniding Equipment Mineral Dressing Process Flow Crushing Grinding Equipment Conveyer Feeding Equipment Flotation Machines Magnetic Separators Laboratory Equipment Environmental Protection Equipment

Outside grinding circuits, Falcon SB Gravity Concentrators are also used for precious metal separation from aggregate or placer deposits. Falcon SB Gravity Concentrators are known as "SemiBatch" Gravity Concentrators because they continually accept feed during the run cycle, but only produce mineral concentrate during periodic rinse cycles.

GRAVITY CONCENTRATION OF GOLD FROM CYCLONE FEED IN . GRAVITY CONCENTRATION OF GOLD FROM CYCLONE FEED IN GRINDING CIRCUITS By Steve McAlister, P. Eng., Colin Sprake, B. Sc. May 4, 1999 1 of 7 Introduction The use of gravity concentration in gold .

WhatsApp)

WhatsApp)