4 High Rolling Mills for sale, New Used |

The # 1 place to find new used 4 high rolling mills for sale. Buy or sell machinery equipment quickly easily

WhatsApp)

WhatsApp)

The # 1 place to find new used 4 high rolling mills for sale. Buy or sell machinery equipment quickly easily

Welcome to International Rolling Mills. Founded more than thirty years ago in Pawtucket, RI, USA, International Rolling Mills, Inc. uses the latest technology when developing dependable and precision rolling mills. ... Rolling mills 2hi/4hi, slitting equipment, and many miscellaneous items. See More. Rolling Mills. New and used rolling mills ...

Apr 26, 2018· YOGIJI DIGI sees itself as an AUTHORITY IN COLD ROLLING. We have engineered and installed wide range of cold rolling mills, skin pass mills as well as bonding mills. Our sustainable designs ...

2 High / 4High Fenn Rolling Mill 24 Views · Posted on 19:30:24. 4HI United Cold Rolling Reversing Mill 48 Views · Posted on 19:30:20. 480mm x 8mm Farmer Norton 4High Reversing Mill 16 Views · Posted on 19:17:24. 515mm x MKW 4High Reversing Cold Rolling Mill

4 Hi Backup Roll Drive Rolling Mill. Machine. GearBox With Combined Pinion Stand. Machine. 4 Hi Coil Mill . Machine. 12 Hi Coil Mill . Machine. 4 Hi Foil Mill . Machine. 4 Hi Work Roll Drive Rolling Mill. Machine. Varia Pratik Engineering is an effortlessly,authentic, handcrafted design that suitable for any business. For expert Machinery ...

As the largest 4 Hi Rolling Mill manufacturer in china, Wuxi Juntoo International trading Co. Ltd sales quality 4 Hi Rolling Mill to customers all over the world.

Used 80" MESTA 4HIGH COLD REVERSING MILL for sale 72227 by National Machinery Exchange Inc in Newark, New Jersey

The 4hi rolling mill unit is composed of motor, gear coupling, reducer, gear coupling, herringbone gear seat, universal joint bracket, universal joint shaft, working machine base, etc. The working roll of the rolling mill is driven by a series of drive mechanisms through a motor.

UEN lists used ROLLING MILLS, 4HI,BLISS,CAUFFIEL,FENN,FROHLING,,MILLS,NASH,ROLLING,UNITED, 0R7604 ROLLING MILLS, 4HI. Try the fully interactive searchable site at The following items are currently available. Please contact the dealer shown directly for more information. Tell them you saw .

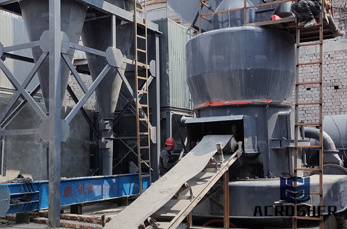

4 Hi Four Roller Cold Rolling Mill Line. Four roller cold rolling mill introduction We have rich experiences in metal coil cold rolling mill design and manufacture, cold rolling mill is for reducing metal coil plate thickness by cold rolling, therefore, also can be called "thickness reducing mill" or "gauge reducing mill".

Feb 10, 2012· 6 High Reversible Cold Rolling Mill 1. CRM Complex6 High Reversible Cold Rolling Mill Training Manual0 2. LINE VIEW 1 3. ... FRONT VIEW REAR VIEWThis Assy. is used to change rolls of 6 High rolling mill USED ROLLS 12 14. SIDE VIEW OF 6 HIGH REVERSIBLE MILL 13 15. OPERATIONAL INSTRUCTIONS A rolling mill should operate at its maximum power or ...

Tags Rolling Mills; 4High Rolling Mills. Fourhigh rolling mills can be put in tandem, two to seven stands, instead of a reversing mill. They can be equipped with load cells to tell the separating force and hydraulic or mechanical screw downs, depending if it is hot or cold rolling.

Nov 28, 2016· A 4high rolling mill can be a small mill or a standalone, high torque, high reduction mill. A typical reversing mill has a quick change roll system. Fourhigh mills can be equipped with roll bend and shape control, a precision consistent product. Old 4high cold rolling mills can be upgraded.

The 2 Hi Cold Rolling Mill is used for making strip/sheets and helps in improving the strength and forming higher tolerance. This machine provides accurate size and output desired by clients and advanced methods of production which directly reflect in higher productivity and reduce the operational cost significantly.

Oct 15, 2019· Find Used or Surplus Rolling Mills, 4 Hi, Mesta, Cauffiel, Morgan, Skoda, Pittsburgh Directory of 70000 listings by 1200 suppliers

A tandem mill is a special type of modern rolling mill where rolling is done in one pass. In a traditional rolling mill rolling is done in several passes, but in tandem mill there are several stands (>=2 stands) and reductions take place successively. The number of stands ranges from 2 to 18.

Element Machinery is an OEM specializing in custom machinery manufacturing, and automated process development. Call us today and let''s build something!

Description: The McElroy applied tube finning machine is a miniature high speed rolling mill synchronized with the rotation and advance of the tube. Quick change, steady rest input and output racks, allow a 1" tube to rotate at up to 3000 RPM.

4Hi Mills Intermediate Finishing Mills. The versatile Waterbury Farrel 4Hi Mill can be deployed as both a nonreversing mill for intermediate rolling and as a reversing mill for finish rolling. Smaller work rolls allow for more efficient material reduction.

Nov 22, 2013· 6. Cold rolling using Roll Coolant emulsion In this CRM, Cold rolling is done on a Mecon Weanunited PLC controlled 3000 tons/m 4 Hi reversible mill. As the name suggests the 4 Hi mill employs 4 rolls, two these are the work rolls and the other two are the backup rolls.

H ydraulic AGC cold rolling mill line introduction Either 4Hi or 6Hi cold rolling mill, either reversible or tandem cold rolling mill, the hydraulic AGC pressdown or pressup system can be available. Hydraulic Automatic Gauge Control is high precision high efficiency...

4Hi rolling mill can adjust the strip crown, change the contact pressure distribution between the rolls. The machine structure is simple, easy to operate.

4. Equipment Level. 1) The main components of the low pressure hydraulic system and the hydraulic pump adopt domestic high quality products; 2) The gears of the important drive equipment reducer, such as the coiler and the main rolling mill, adopt the hard tooth surface grinding gear; the bearings of the coiling machine and the main rolling mill reducer are selected with domestic high quality ...

Rolling mill consisting of four rolls or known as a 4 High rolling mill is used for reducing material to extremely small thicknesses. Through the use of larger backup rolls, the issues of roll deflection can be avoided and smaller work rolls can be used.

WhatsApp)

WhatsApp)